Pneumatic tapping machine is to use compressed air as power, through air pressure regulator connected to the pneumatic motor, air pressure through a high-pressure air valve into the inside of the motor, drive motor rotor blade axial spinning force, after the rotor movement by the torque of gear output power driven tap tapping operations. The tapping machine’s working air pressure is according to the tap size and product material.

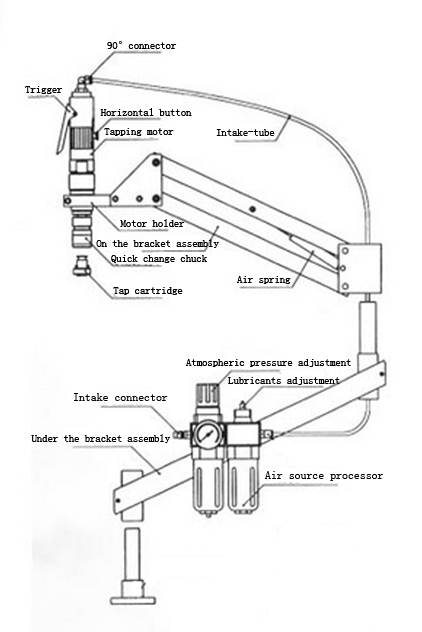

Pneumatic tapping machine structure is simple, has installation, rack, lever set, machine core, tapping chuck.

1. Installation, in order to let the machine light and easy to move, tapping machine can be installed in the machine tool working platform, iron work pieces, permanent magnet or mobile car;

2. Rack, can rotate or lifting;

3. Lever set, can make the machine lifting of elastic reset or rotating at the same time;

4. Machine core, rotating achieve universal tapping, can also instant change speed;

5. Tapping chuck, when torque overload, can protect the chuck, prevent slippage, won’t make tap broken.

Pneumatic tapping machine uses for car or motorcycle body, frame, chassis, connecting rod, engine, and various mechanical parts, machine tools, metal products, metal pipe, gear, valve parts processing. Pneumatic tapping machine is portable, flexible, efficient, repeated positioning speed is quickly and scope of work is big, operation is safe etc. advantages which unable to replace other similar devices.