Hydraulic damper is a device that to reduce the resistance of movements, and then depletes the kinetic energy. Hydraulic damper is widely used in automotive and medical equipment; the feature is the resistance changes with running speed. Obviously, it can play a buffer role in connected institutions. The most important feature is that the force of the gas spring changes with velocity of movement. Significantly, when the force point of gas spring movement faster, then the resistances of the spring is increased. In other case, when the force point movements is slow, almost no resistances.

The use and production process of Multiple Spindle Machine

Multiple Spindle Machine use

Multiple Spindle Machine also known as Multiple Spindle Head, Porous Drill, Multiple Spindle Drill Machine or Multiple Spindle Machine Tool, is a new hole processing equipment. It is mainly used for quick drilling, tapping, chamfering, countersink plane work, has the characteristics of high production efficiency, low cost etc. A typical ordinary Multiple Spindle Machine with a typical ordinary Drilling Machine can put several or even dozens of twenty holes or thread treatment one time. With the development of domestic auto part, the competition between every part suppliers are fierce, so select Multiple Spindle Machine of high performance, high efficiency is a very efficient way of the enterprise to reduce the production cost, enhance the competitiveness of enterprises,

Multiple Spindle Machine production operation process

First, preparation

1, Before entering the production job, die casting worker must wear labor protection articles.

2, Check the water, electricity, gas, wind etc. is whether compliance production specification.

3, Prepare for other before production.

Second, no-load startup

1, Multiple Spindle Machine has function-load test. Open the start switch, wait motor and oil pump operation run 1 ~ 3 minutes.

2, Manual operation no-load commissioning. Check the electric control cabinet, program instructions signal whether according to the procedures.

3, No-load commissioning.

Third, the production operation

1, According to the process to adjust various parameters. And adjust corresponding temperature parameters.

2, Preheat mold and spoon scoop, preheat the cold chamber die casting machine injection cylinder.

3, After remove the parting surface, nozzle etc. harm the safety of others factors manual operation, test roduce prototype part and test product by oneself.

4, Verify that the product meets the drawing, the equipment meets the process procedures, can be produced in single cycle. Should be closes the security door when production. Somebody is strictly prohibited to stand in parting surface.

5, Automatic production. Approved by the “three inspection” of qualified products can be fully automated mass production.

6, Found fault in production, it is necessary to stop the machine immediately to check, adjust and fill in the trouble ticket, after Multiple Spindle Machine troubleshooting can normal production.

Fourth, the production end

1, Downtime. Check every equipment.

2, Clean equipment. Filling all lubricating points surface grease so that anti-corrosion, rust.

How to choose the Tapping Machine and Tapping Machine commonality

Tapping Machine is also called Thread Tapping Machine, every industry is requires a device. Now on the market has many different kinds of Tapping Machines, pneumatic, electric, hydraulic, etc., but the Pneumatic Tapping Machine is one of the best alternatives to traditional Tapping Machine. Pneumatic Tapping Machine on the price is very affordable, its operation is simple, the tap is not easy to broken, and in terms of moving very deft, compared with electric, pneumatic is generally three to five years longer life; Electric Tapping Machine, the cost is higher, compared with the pneumatic, service life is short, but has the advantage in terms of fangs, thread diameter is bigger can choose Electric Tapping Machine; Hydraulic Tapping Machine volume is relatively large, can affect production efficiency.

Tapping Machine of steel, iron, but PURROS Tapping Machine is made of aluminum, because compared with steel and iron, the density of aluminum is small, high intensity, affordable, quality is light is the most important, in this way, move conveniently specially, greatly improve production efficiency. In general, how to choose the Tapping Machine still depends on the buyer’s need and preference.

Many hardware factory production products are very many, many products require tapping this step. But previous artificial cheap, hiring is easy, so a lot of manufacturers didn’t thought of using Automatic Tapping Machine. In recent years, many areas in hiring, wages rise, people more difficult situation, many hardware manufacturers realize the importance of Automatic Tapping Machine, because this is a best way to reduce manpower. As many customers Tapping Machine not particularly understand, they call me a will ask our Tapping Machine function in general? In fact, not all of the work piece can be made universal Tapping Machine.

First we need to know the shapes of work piece, processing precision requirement, the work of the artifact itself etc. If the work piece shape is same, only is appearance size some of difference is you can make it universal Automatic Tapping Machine, premise is the processing precision requirement is not high; But if the shape is different, it is hard to do it. As the manufacturer of Automatic Tapping Machine, we still suggest customer if a particularly large amount of artifacts, or to make special machine is better, because it’s Automatic Tapping Machine, stability is good, in order to achieve less investment, high efficiency of the effect.

![]()

Drilling Machine Fixture type and application

Fixture is used for cutting the work piece in the process of guide cutting tools and fixed position and supporting work piece clamping device. Fixture is roughly divided into two kinds: Drilling Fixture and Boring Fixture. Among them the Drilling Fixture is most common. Drilling Fixture is for short of Drilling Jig, mainly used for machining hole and screw thread. It is mainly composed of drill set, drill template, positioning and clamping device. The main types are:

(1) Fixed Type Drilling Jig, in use, this kind of Drilling Jig is mainly used for Vertical Drilling Machine machining large diameter single span or Radial Drilling Machine processing parallel hole. Drilling Jig position is fixed on the machine tool, and machining precision is higher.

(2) Sliding Column Type Drilling Jig, is general adjustable fixture with elevating drilling templates. This Drilling Jig has simple structure, convenient operation, action quick and short manufacture cycle advantages, widely used in the production.

(3) Cover Board Type Drilling Jig, this drilling jig no specific folder, its positioning elements and clamping device is directly installed on the drill template. Drill templates in work piece jacket, suitable for big volume, heavy work piece machining of holes. Fixture structure is simple and light, easy to remove scraps; But each fixture should be from the work piece loading and unloading, time consuming, so the weight of the drill fixture should be smaller.

(4) Rotary Type Drilling Jig, this type Drilling Jig can work out several on the work piece around the spindle of the distribution of the spindle or radial hole, because Drilling Jig with dividing device.

(5) Tilting Type Drilling Jig, its structure is simple, Drilling Jig processing generally manually flips, so fixture and work piece are lighter. It can reduce the number of installation, improve the processed hole position accuracy. So is mainly used for machining small work piece of different on the surface of the pores.

Hydraulic Damper principle and advantage

Hydraulic Damper Is a kind of hydraulic equipment, in order to reduce piston motion and both ends of the oil cylinder occur strike, at the bottom of the oil cylinder can installed damper. If install in the central oil cylinder, also can have the effect of adjusting the oil cylinder movement rhythm. Hydraulic Damper principle is: in the pipeline or equipment normal thermal expansion, with hydraulic damper to move slowly, at that time almost no damping force; When load transient, Hydraulic Damper valve is activated, at this point it produces with vibration force the same size reverse resistance, prevent vibration of the pipeline or equipment to reduce larger amplitude, reduce the amplitude, so as to protect the piping or equipment effect.

Hydraulic Damper is widely used in automotive, medical equipment, washing machine, refrigerator etc. industries, because the damper has apparatus has resistance with the running speed change, dampening effect on the speed of the connected institutions etc. characteristics. And its advantages are many, such as: large damping force, wide load range, quick, long work schedule and so on, especially suitable for low frequency and large amplitude conditions environment. Like all kinds of higher or lower than the normal temperature, high humidity high salinity, dust, nuclear radiation and other working conditions. Such as water hammer, air hammer, safety valve exhaust steam, boiler explosion and earthquake, etc.

How to choose the power head

Select power head type according to different conditions, we should pay attention to the following:

1, the size of the drill hole, determines the diameter of the power head drill.

2, how much the depth of drill hole, it is a blind hole or a through hole.

3, what is the material of processing work piece? Because different material’s hardness is different, the required power head is also different.

4, use pneumatic or hydraulic drive? Because both have a greater difference.

5, what is installation way? Horizontal type, vertical type, backstroke type or inclined type.

6, how much is the requirement of rotational speed (cutting speed)?

7, how much is the required motor power in normal work?

8, what is kind of belt form? Triangular belt, synchronous belt or chain?

9, what is king of chuck form? Such as ER model, AS model, JT model, MT model, NT model and so on.

Different power head effect is different, the range of application are also different. Such as hydraulic driven power head, is suitable for processing large hole, feeding intensity big, hard material work piece, but the heavier in weight. And pneumatic driven power head, is suitable for processing small hole, feeding intensity small, back speed high, light weight work piece, use very convenient, but can’t processing more hard material.

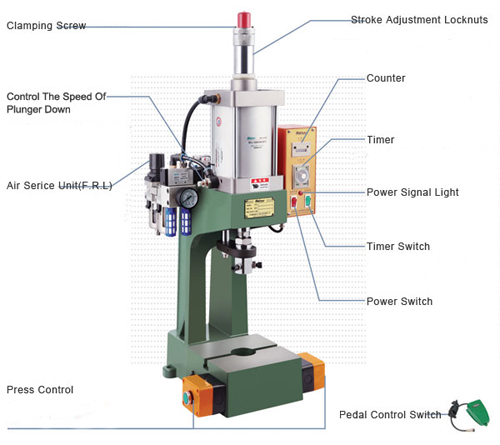

Pneumatic Press part and design feature

Pneumatic press with compressed air as power source, through the pipeline for solenoid valve, through the foot switch to control the action of electromagnetic valve to control the cylinder forward and back, and then achieve the goal of punching.

Which parts does pneumatic press have?

Power Switch: On/Off switch.

Timer Switch: On-control active time, Off-manual control.

Counter: Zero function, to know daily production, easy to control the cost.

Timer: Control pressure time.

Pedal Control Switch: Applicable to connect with controller box socket.

Lock Screw: Control movable base, when adjust the height of movable base, need to loosen the two locking screws. Movable base do an up and down moving, it is used to adjust the gap between it and vertical column. Fasten locking screws after finish adjusting gap.

Cylinder stroke adjustable: Lock screw need to relax, can adjust stroke at 50mm.

Adjusting handle of the work table: To adjust the height of work table.

Control the Speed of Cylinder Down: The machine moves more smoothly.

Air Service Unit (F.R.L.): Control pressure range, easy to pressure distribution efficiency.

Press Control: Two hands safety push buttons, and foot switch operation option.

In addition to the above parts, there are three kinds of auxiliary parts is optional.

Speed Venting Valve: If you need rapid decline, you can install it speed venting valve before work.

Pressure sensor: Measure the pressure while assembly.

Safety Optical Fence Protection: Keep personal safety while operation.

Pneumatic press has simple structure, is not easy to deformation; Performance is good, the space can be arbitrary adjustment; Cylinder with rotation stopper guide rod, make the work more accurate. With both hands button switch or pedal switch, timer and counter, makes the pneumatic press simple and convenient operation, greatly improve the working efficiency, reduces the labor force, also can control the cost of production.

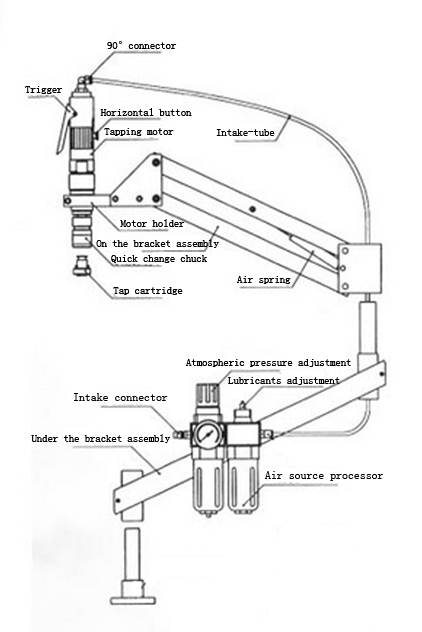

The principle and characteristic of pneumatic tapping machine

Pneumatic tapping machine is to use compressed air as power, through air pressure regulator connected to the pneumatic motor, air pressure through a high-pressure air valve into the inside of the motor, drive motor rotor blade axial spinning force, after the rotor movement by the torque of gear output power driven tap tapping operations. The tapping machine’s working air pressure is according to the tap size and product material.

Pneumatic tapping machine structure is simple, has installation, rack, lever set, machine core, tapping chuck.

1. Installation, in order to let the machine light and easy to move, tapping machine can be installed in the machine tool working platform, iron work pieces, permanent magnet or mobile car;

2. Rack, can rotate or lifting;

3. Lever set, can make the machine lifting of elastic reset or rotating at the same time;

4. Machine core, rotating achieve universal tapping, can also instant change speed;

5. Tapping chuck, when torque overload, can protect the chuck, prevent slippage, won’t make tap broken.

Pneumatic tapping machine uses for car or motorcycle body, frame, chassis, connecting rod, engine, and various mechanical parts, machine tools, metal products, metal pipe, gear, valve parts processing. Pneumatic tapping machine is portable, flexible, efficient, repeated positioning speed is quickly and scope of work is big, operation is safe etc. advantages which unable to replace other similar devices.

Transmission classification and function

A device of changes in machine tool, auto, tractor etc. machine running speed or traction, composed of many different diameter size of the gear. Usually installs in the engine between main drive shaft and driven shaft. Transmission is a gear drive device that can be fixed or tranche change the output shaft and input shaft transmission ratio, also known as the gearbox.

According to the transmission ratio change way, transmission can be divided into a step-type, stepless type and comprehensive type.

1, step-type transmission, it is one of the most widely used. It adopts gear drive, has a number of optional fixed transmission ratio. According to the different gear train type used, there are two kinds of axis fixed transmission and axis rotary transmission.

2, stepless type transmission, it is to point to any transmission ratio can be gained continuous variable speed range of variable speed system. Through the stepless variable speed can get the best match between the transmission and engine working conditions. Common stepless transmission has hydraulic type, mechanical and electric type, etc.

3, comprehensive type transmission, it is to point to by step-type transmission and stepless type transmission combined the transmission, the transmission ratio can be several discontinuities between the maximum and the minimum range of stepless change.

According to the operation manner, transmission can be divided into mandatory operation manner, automatic operation manner and semi-automatic operation manner.

1, mandatory operation manner transmission: rely on the driver directly operation the shift lever to change gear.

2, automatic operation manner transmission: the choice of transmission ratio and the gear shift are automatic. Drivers need to operate the speed up accelerator pedal, transmission can according to engine load signal and speed signal to control executive component, implement gear change.

3, semiautomatic operation manner transmission: can be divided into two kinds, one kind is part of the automatic gear shift, part of the gear shift compulsory; Another kind is with a button the selected gear in advance, while on the clutch pedal or loosen the accelerator pedal, shift by enforcement agencies themselves.

Transmission is one of the main components in the automobile drive train. Because the transmission in a wide range, can change the size of the motor speed and the size of the car on the driving wheel torque; as well as can achieve reverse driving and implementation gap. Auto transmission generally is composed of box body and box body after before, it is by changing the gear ratio, change torque of the engine crankshaft, adapt to drive the starting, acceleration, and overcome various under different driving conditions, such as road block on the drive wheel traction and speed of different needs.

Mechanical equipment risk factor and protective measure

Mechanical equipment risk mainly is the movement part of the equipment, such as transmission mechanism and cutter, movement work piece and chip, etc. If the equipment has defect, protective device failure or improper operation, it could cause personal casualty accident at any time.

1, mechanical transmission mechanism can be divided into gear transmission, chain transmission and belt transmission. If the component does not conform to the requirement, such as mechanical design is unreasonable, transmission part and outstanding transmission part exposed, unprotected, etc., or its own security protection consciousness is poor, don’t be careful and peccancy operation may handle, clothes haul in the harm.

2, mechanical equipment rotating parts and moving parts, mechanical equipment, has a very big risk. Its rotating parts, such as drill, wrap silk machine rotating work piece chuck, etc. once with people clothing, sleeves, long hair entwined, easy life or personal injury accident; Operator operation method is undeserved, too hard, use the tool specification is unreasonable, are likely to make the operator bumped on machine tools. The operator and construction personnel stand position is not appropriate; Cutter cuts etc will pose a threat to personal safety.

Therefore, do some protective measures for mechanical equipment. For example mechanical transmission mechanism, for safety protection gear transmission, you must install protective device fully enclosed, without a guard shall not be used; for safety belt drive, adopt the method of the belt cover all, or installation of protective railings for protection. For coupling safety protection, the most fundamental way is to add shield. To install safety device, such as overload safety device, travel insurance device, brake device, etc.

As a worker, operating equipment must be in strict accordance with the required dress; when the machine is running, no adjustment or measuring the work piece with hands; work piece and cutter card wants firm, banned touch rotating parts of the machine. Please responsible for own safety.